What is the accuracy and repeatability of cuts made with a CNC laser cutter?

Machine Calibration: CNC laser cutters require meticulous calibration to ensure precise cutting. Calibration involves aligning the laser beam path, focusing the beam correctly, and setting the optimal distance (focal length) between the cutting head and the material surface. Even slight misalignments or incorrect focal settings can lead to variations in cutting depth and edge quality.

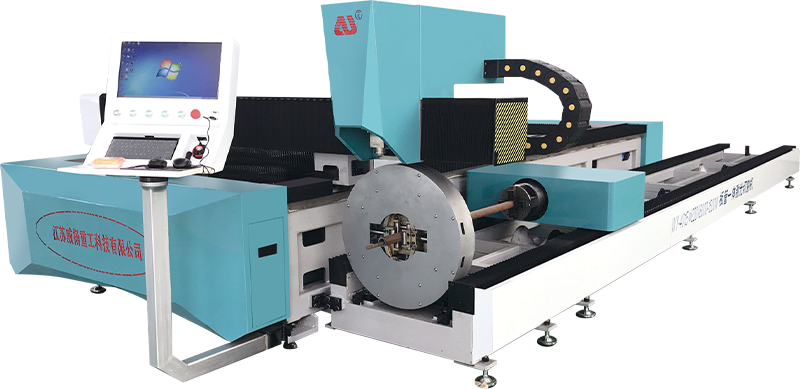

Motion Control System: The motion control system of a CNC laser cutter dictates how accurately and smoothly the cutting head moves along programmed paths. It comprises precision components such as servo motors or stepper motors, linear guides, and feedback mechanisms (like encoders) to ensure accurate positioning. High-resolution encoders and advanced control algorithms enable the cutter to follow intricate cutting patterns with minimal deviation. Rigorous testing during production and periodic recalibration ensure the system maintains its specified accuracy throughout its operational life.

Laser Beam Quality: The quality of the laser beam significantly influences cutting precision and edge quality. Laser beams are characterized by parameters such as wavelength, beam profile (Gaussian or TEM00 mode preferred for focused cutting), beam divergence (how the beam spreads over distance), and coherence length (related to the stability of the beam). Quality laser sources, such as CO2, fiber, or diode lasers, produce beams with consistent characteristics, essential for achieving sharp, clean cuts across various materials. Advanced laser optics and beam delivery systems minimize beam distortions and maximize cutting efficiency.

Material Properties: Materials respond differently to laser cutting due to their thermal conductivity, reflectivity, and hardness. These properties influence the optimal cutting parameters required for precise results. For instance, metals like stainless steel or aluminum conduct heat efficiently and may require adjustments in laser power and cutting speed to maintain edge quality and dimensional accuracy. Reflective materials necessitate the use of protective gases (e.g., nitrogen) to prevent oxidation and maintain cutting consistency. Understanding material behavior and selecting appropriate cutting techniques ensures optimal performance and minimizes material waste.

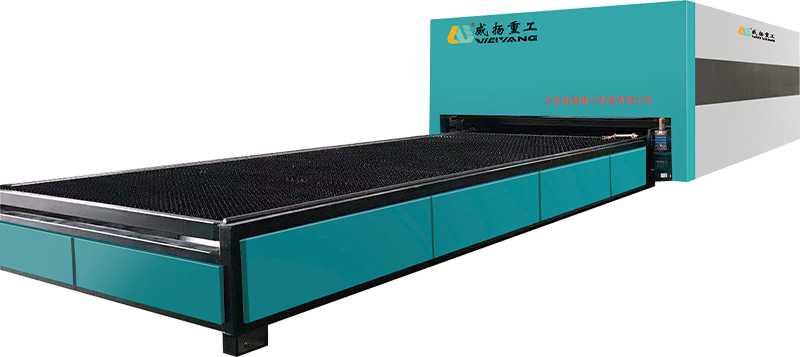

Cutting Speed and Power Settings: Achieving precise cuts involves optimizing cutting parameters such as laser power, cutting speed, assist gas pressure, and focus depth. These parameters interact to control the depth and quality of the cut, influencing factors like kerf width (width of the cut), heat-affected zone (HAZ), and edge smoothness. Fine-tuning these settings is crucial for balancing cutting speed with edge quality and minimizing post-processing requirements. Modern CNC laser cutters often feature automated parameter adjustment based on material type and thickness, enhancing efficiency and repeatability while maintaining cutting precision.